When it comes to maintaining a commercial kitchen, cleanliness and sanitation are paramount. A clean kitchen not only ensures the safety and wellbeing of patrons but also complies with health regulations. This comprehensive guide will explore the best ways to clean a commercial kitchen through three primary methods: manual cleaning, mechanical cleaning, and clean-in-place cleaning. It elaborates on the importance of maintaining hygiene and addresses frequently asked questions about recommended chemicals and the frequency of these cleaning routines.

Manual cleaning

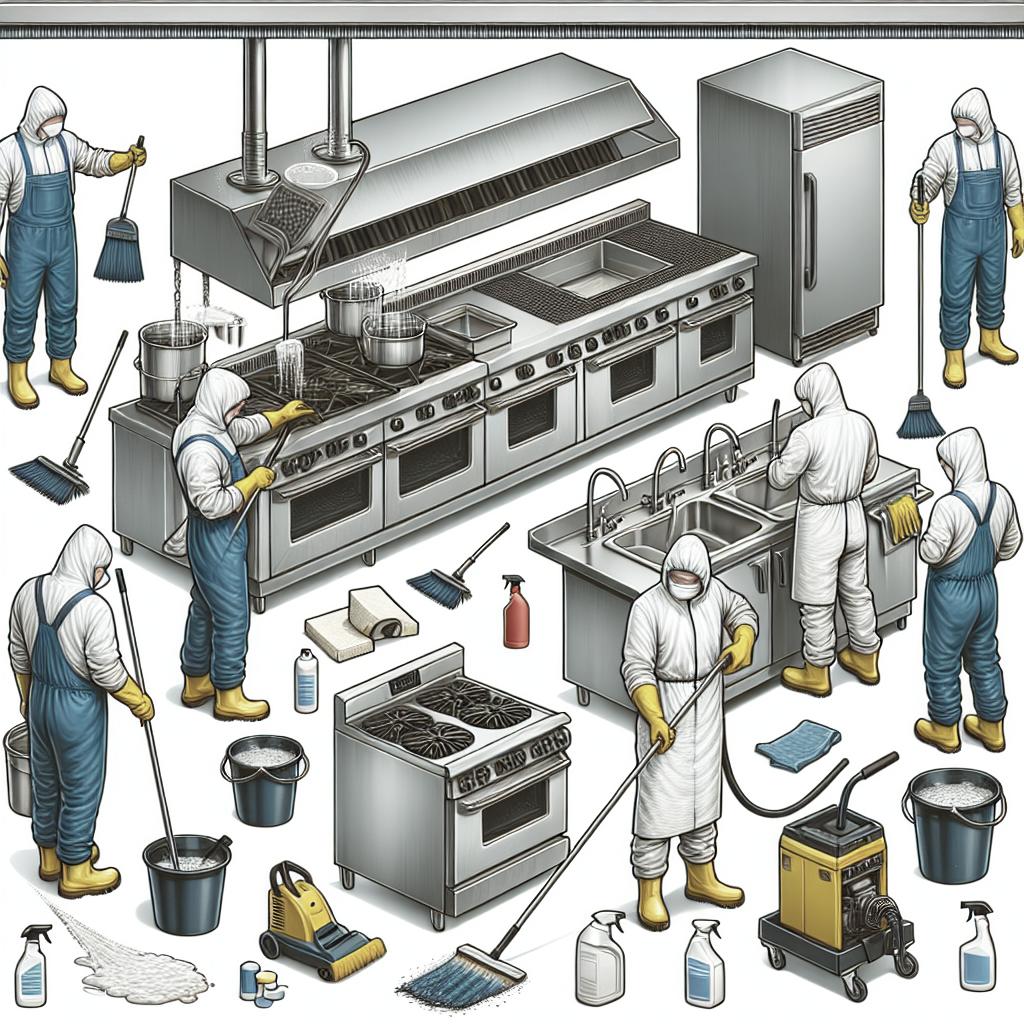

Manual cleaning requires human effort and basic cleaning tools like brushes, mops, buckets, and cloths. This method is crucial for cleaning areas that machines can’t reach, such as small crevices, corners, and intricate kitchen equipment. One of the most effective ways to perform manual cleaning is by using a structured approach, often referred to as the “clean-in-place” procedure for smaller, detachable equipment. Start with removing visible debris, followed by scrubbing with hot water and a degreasing detergent. Rinse thoroughly and sanitize the surfaces with an appropriate chemical sanitizer, ensuring it meets health and safety guidelines. Be sure to let the sanitizer air dry to maximize its effectiveness. Manual cleaning also covers the routine tasks such as wiping down surfaces, cleaning out refrigerators, and scrubbing grills. These tasks require dedication and consistency, particularly in high-traffic areas of the kitchen. Regular manual cleaning can prevent the buildup of grime, grease, and potential foodborne pathogens, maintaining a hygienic and safe cooking environment.

Mechanical cleaning

Incorporating machinery into the cleaning process can significantly enhance efficiency and effectiveness. Mechanical cleaning methods include the use of dishwashers, floor scrubbers, and specialized cleaning machines for items like hoods and vents. Dishwashers in a commercial kitchen are paramount for ensuring that cooking utensils, plates, and glasses are not only clean but properly sanitized. Machines operate at high temperatures and use approved chemicals to guarantee that items are free from pathogens. It is essential to regularly check and maintain these machines to ensure they function correctly, as a malfunctioning dishwasher can quickly lead to hygiene issues. Floor scrubbers and steam cleaners are essential for maintaining clean floors in a busy kitchen setting. Using a combination of hot water, cleaning solutions, and mechanical scrubbing, these machines can remove grease and food particles more effectively than traditional mopping. For hoods and vents, specialized cleaning machines help remove grease build-up which, if left untreated, can become a fire hazard.

Clean-in-place cleaning

Clean-in-place (CIP) cleaning is a method often used in industries where contamination prevention is critical, like food processing and pharmaceuticals. This technique can also be adapted for commercial kitchens for equipment that is difficult to disassemble or move. The process involves circulating a cleaning solution through the machinery without having to dismantle it. In commercial kitchens, this can be used for items such as beverage dispensers, fryers, and ice cream machines. The CIP system typically follows a defined cycle, which includes pre-rinse, detergent wash, post-rinse, and sanitizing steps. Regular CIP cleaning ensures that even the hidden and hard-to-reach parts of the equipment are sanitized, thus reducing the risk of contamination. Ensuring that staff are properly trained to execute these automated cleaning cycles is essential for maintaining the effectiveness of a CIP system.

The importance of cleaning and sanitizing

Cleaning and sanitizing are foundational practices in any commercial kitchen. Failure to maintain proper hygiene can result in foodborne illnesses, poor customer reviews, and potential legal action. In addition, a clean kitchen can enhance the quality of food produced, resulting in better customer satisfaction and increased business. Sanitizing goes beyond cleaning; it involves reducing the number of bacteria and pathogens to safe levels. This is especially important in a commercial kitchen setting where multiple food types—some raw, some cooked—share the same space. Regular sanitizing of surfaces, utensils, and equipment prevents cross-contamination and ensures a safer dining experience for customers. Moreover, maintaining a schedule and using the appropriate cleaning and sanitizing agents can prolong the lifespan of kitchen equipment. By regularly removing grease and grime build-up, you minimize wear and tear, reducing maintenance costs in the long run.

Frequently Asked Questions

What specific chemicals or detergents are recommended for each cleaning method in commercial kitchens?

For manual cleaning, it is advisable to use a high-quality degreasing detergent followed by a sanitizer approved for food environments, such as quaternary ammonium compounds or chlorine-based sanitizers. For mechanical cleaning, dishwashers should use detergents and rinse aids specifically designed for commercial use. Floor scrubbers often use a combination of a neutral pH cleaner and a degreasing agent for effective cleaning. CIP systems typically require a combination of caustic cleaners and acid detergents for thorough disinfection, followed by a sanitizer.

How often should each type of cleaning (manual, mechanical, clean-in-place) be performed in a commercial kitchen?

Manual cleaning should be performed daily, with surfaces wiped down multiple times a day to prevent the buildup of grime and bacteria. Mechanical cleaning, such as using dishwashers and floor scrubbers, should also be a daily task, ensuring all used utensils and high-traffic areas are cleaned thoroughly. Clean-in-place cleaning should be conducted according to the equipment’s usage and manufacturer’s guidelines, often weekly or bi-weekly, to maintain optimal and efficient operation.

| Cleaning Method | Description | Recommended Frequency |

|---|---|---|

| Manual Cleaning | Involves human effort, basic tools for cleaning hard-to-reach areas and routine tasks | Daily |

| Mechanical Cleaning | Utilizes machines like dishwashers, floor scrubbers, and specialized cleaning equipment | Daily |

| Clean-in-Place Cleaning | Circulates cleaning solution through machinery without dismantling | Weekly/Bi-Weekly based on equipment usage |

By integrating these cleaning methods and maintaining consistent routines, commercial kitchens can uphold their reputation, ensure safety, and increase efficiency. Investing in proper training and using the best cleaning agents will further enhance these benefits, creating a pristine culinary environment. Keep your kitchen clean, and your business will reap the rewards.